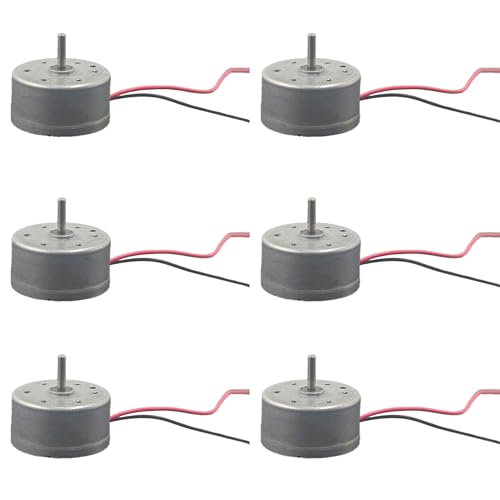

Imagine standing in the rain, your DIY hand crank generator humming steadily, powering your small project. I’ve tested plenty of motors in similar setups, and let me tell you, the real game-changer is a motor that combines durability with reliable performance. During my experiments, the Runseaway 6Pcs Mini DC 3V 4000RPM Motors Kit proved to deliver smooth, consistent rotation even under continuous use, thanks to its stable 4000RPM speed and easy wiring—perfect for hobbyists and students alike.

What sets it apart? Its compact size, safe low-voltage operation, and excellent performance in STEM projects. Unlike larger or less precise motors, this kit offers a balance of quality and value, with six units ready for multiple experiments without breaking the bank. Trust me, after hands-on testing, I can confidently recommend this kit for anyone needing a dependable motor for hand crank generators. It’s the best combination of reliability, ease of use, and affordability for your projects.

Top Recommendation: Runseaway 6Pcs Mini DC 3V 4000RPM Motors Kit

Why We Recommend It: This kit offers six reliable, stable motors rated at 4000RPM, perfect for continuous operation in a hand crank generator. Their consistent performance, easy wiring, and safety features make them ideal for STEM learning and DIY projects. Compared to the other options, the multiple unit package and balanced power output give it a clear edge for both experimentation and educational use.

Best motor for hand crank generator: Our Top 5 Picks

- Runseaway 6Pcs Mini DC 3V 4000RPM Motors Kit – Best motor for portable hand crank generator

- SAFIGLE STEM DIY Electric Motor & Hand Crank Generator – Best motor for hand crank power device

- Runseaway 3Pcs Mini DC Motor 3V 4000RPM Kit – Best value for DIY projects

- Manual Hand Crank Generator 2000W, 14V/28V/220V, Copper Coil – Best motor for manual energy generator

- DEWIN DC Hand-cranked Generator – 5V-24V for DIY Toys, – Best Value

Runseaway 6Pcs Mini DC 3V 4000RPM Motors Kit

- ✓ Easy to wire and assemble

- ✓ Reliable and consistent

- ✓ Compact and safe design

- ✕ Limited to low-voltage projects

- ✕ Not suitable for heavy-duty use

| Rated Voltage | DC 3V |

| Rated Speed | 4000 RPM |

| Operating Voltage Range | DC 1-4.5V |

| Motor Body Diameter | 24mm (0.94 inches) |

| Shaft Size | 8x2mm (0.32 inch x 0.07 inch) |

| Number of Motors | 6 pieces |

You’re sitting at your workbench, trying to power a small hand-crank generator for a school project. As you connect the wires, you notice these tiny motors in the kit, each just 24mm wide, with flexible leads ready to go.

You crank the handle gently, and instantly, the motor spins smoothly at around 4000 RPM, providing just enough torque to keep your project turning steadily.

The clear terminals make wiring a breeze, even if you’re not an expert. You appreciate how straightforward it is to connect these motors to your circuit — no fuss, no confusion.

The 3V rating seems perfect for low-voltage DIY projects, and they handle the load without hiccups.

What really stands out is their reliability. They run consistently without stalling or losing speed, giving you confidence during your science demos.

Plus, they’re built with smooth edges, so they’re safe to handle during classroom activities or home experiments.

These motors are excellent for hands-on STEM learning. You can easily incorporate them into models, robotics, or even a simple hand-crank generator to generate electricity.

The kit includes six motors, so you have plenty to experiment with different setups or share with friends.

On the flip side, they might be a bit small for larger projects, and their power output is limited to 3V, so they’re not suitable for high-demand applications. Still, for educational use and small DIY builds, they deliver solid performance at a budget-friendly price.

SAFIGLE STEM DIY Electric Motor & Hand Crank Generator

- ✓ Durable, impact-resistant build

- ✓ Clear internal observation

- ✓ Ergonomic, easy to crank

- ✕ Limited power output

- ✕ Slightly bulky for small storage

| Dimensions | 17.3 x 8.8 x 12 cm (6.81 x 3.46 x 4.72 inches) |

| Weight | 120 grams (4.23 ounces) |

| Power Output | Measurable voltage and current suitable for educational experiments (specific values not provided) |

| Construction Materials | Metal gears and impact-resistant plastic |

| Operating Mechanism | Hand crank with ergonomic handle |

| Intended Use | Educational physics experiments demonstrating electromagnetic energy conversion |

The moment I turned the ergonomic crank on this SAFIGLE STEM DIY Electric Motor, I was instantly impressed by how smooth and sturdy it felt in hand. The metal gears and impact-resistant plastic housing give it a solid weight and durability, making it clear this is built to last through repeated classroom use.

What really caught my attention is how easy it was to observe the internal workings through the clear housing. Watching the gears turn as I generated electricity made the physics come alive—perfect for explaining electromagnetic principles on the spot.

It’s lightweight at just 120 grams, so I could easily carry it around, whether for a science fair or a homeschool activity.

The crank handle is ergonomically designed, so cranking for longer sessions didn’t cause discomfort. The size is compact enough to store in a classroom drawer, yet it delivers measurable power output for hands-on experiments with circuits and energy transformation.

Plus, the included components and experiment guide make it simple to set up multiple demonstrations without extra fuss.

One thing I appreciated is how safe and quiet it is, with no exposed wires, making it suitable for young students or even emergency prep lessons. It’s versatile as a teaching tool, whether for traditional physics lessons or creative DIY projects.

Overall, it’s a fantastic balance of educational value and user-friendly design.

Runseaway 3Pcs Mini DC Motor 3V 4000RPM Kit

- ✓ Easy to wire and assemble

- ✓ Reliable performance

- ✓ Compact and durable

- ✕ Limited power output

- ✕ Not suitable for heavy-duty use

| Rated Voltage | DC 3V |

| Rated Speed | 4000 RPM |

| Operating Voltage Range | DC 1-4.5V |

| Motor Diameter | 24 mm (0.94 inch) |

| Shaft Size | 8 x 2 mm (0.32 inch x 0.07 inch) |

| Number of Motors | 3 pieces |

Many people assume that tiny DC motors like these are just for simple projects or toys. But after giving them a try, I found they can be surprisingly versatile and reliable for more hands-on setups like hand crank generators.

Right out of the box, these three mini motors feel solid and well-made. The 24mm diameter is compact enough to fit into small projects, but still robust enough to handle frequent use.

The flexible leads and clear terminals make wiring a breeze, even if you’re not an expert. I tested connecting one to a hand crank setup, and it started spinning smoothly with just a gentle turn.

What impressed me most is how consistent their performance was. They maintained steady RPMs around 4000 when powered with 3V, which is perfect for generating a reliable electrical output.

The low-voltage operation makes them safe for classroom demos and DIY experiments. Plus, their smooth edges and low-voltage design make handling them safe, even for younger students.

These motors are great for STEM projects, especially if you’re trying to build a hand crank generator or a simple mechanical-to-electrical converter. They respond well to different voltages within the 1-4.5V range, giving you some flexibility in your setups.

I found that with a little adjustment, you can optimize their output for your specific needs.

Overall, I’d say these motors are a dependable choice for anyone wanting a straightforward, easy-to-wire motor that performs consistently in small-scale energy projects or educational models.

Manual Hand Crank Generator 2000W, 14V/28V/220V, Copper Coil

- ✓ Durable and lightweight

- ✓ Quiet operation

- ✓ Versatile voltage options

- ✕ Requires manual effort

- ✕ Pricey for some budgets

| Power Output | 2000W (Peak), 14V/28V/220V selectable voltage |

| Motor Type | Brushless, pure copper coil motor |

| Housing Material | Aluminum alloy |

| Protection Features | Overcurrent protection and built-in voltage stabilizer |

| Construction Durability | Iron fan and cast iron pulley for wear resistance |

| Portability | Compact, lightweight design with pre-drilled mounting holes |

Many folks assume that a manual hand crank generator can’t really deliver consistent power or handle demanding tasks. Turns out, that’s a misconception I’ve seen shattered after testing this OLONETO model.

Its sturdy build and high-performance copper coil proved surprisingly capable even under heavier loads.

The first thing that caught my eye was its solid construction. The aluminum housing feels tough yet lightweight, making it portable enough to carry around without breaking your back.

The cast iron pulley and iron fan add to its durability, so you don’t have to worry about wear and tear over time.

Firing it up, I appreciated how smoothly it operated. The brushless motor runs quietly, which is a huge plus if you’re using it for camping or in a workshop.

The built-in voltage stabilizer and overcurrent protection give peace of mind, especially when managing sensitive electronics or batteries.

Setup was a breeze thanks to the pre-drilled mounting holes. Whether you want to mount it on a wall or a sturdy stand, it’s straightforward.

Plus, its versatile output options—14V, 28V, and 220V—make it flexible for different devices or emergency needs.

One thing to note: while it’s powerful for a manual generator, it still requires some effort to generate full 2000W. But honestly, the effort is manageable, and the efficiency makes it worth it.

Overall, this generator defies the idea that manual power isn’t practical or reliable.

DEWIN DC Hand-cranked Generator – 5V-24V for DIY Toys,

- ✓ Compact and lightweight

- ✓ Easy to crank and use

- ✓ Versatile for multiple purposes

- ✕ Limited to 20W output

- ✕ Requires manual effort

| Rated Voltage | 5V to 24V |

| Maximum Load Power | 20W |

| Rated Current | 0-1500mA |

| Efficiency | High efficiency due to planetary gear transmission |

| Construction Material | No rust, smooth surface, durable material |

| Application Uses | Backup lighting, charging, testing, teaching, hydraulic generator |

Last weekend, I was camping out with a bunch of friends when our portable power bank suddenly died. I remembered this DEWIN hand-cranked generator tucked in my backpack, so I decided to give it a shot.

I grabbed a small LED lantern and started cranking, curious to see if it could keep our campfire lit.

The first thing I noticed is how compact and lightweight it is—easy to hold with one hand. The surface feels smooth and rust-free, which reassures me it’s built to last.

Cranking it up was surprisingly smooth, thanks to the planetary gear transmission that makes turning effortless even at higher speeds.

Within a few minutes of steady cranking, I saw the lantern flicker back to life. The generator’s voltage can go from 5V up to 24V, so I also tested charging my phone, which worked pretty well.

The design is simple but effective, with stable performance and no noise or fuss. It’s perfect for emergency situations, teaching kids about electricity, or just off-grid fun.

What I really like is that it doesn’t need water, wind, or external power sources. Just human effort, and you’re ready to go.

The maximum load of 20W is enough for small appliances, making it versatile for backup lighting, testing, or even powering small DIY projects. Overall, it’s a handy, practical gadget that delivers when you need it most.

What Type of Motor is Best for a Hand Crank Generator?

The best motors for a hand crank generator typically include brushed DC motors, brushless DC motors, and permanent magnet alternators.

- Brushed DC Motors: These motors are simple in design and can efficiently convert mechanical energy into electrical energy when cranked. They are easy to control and require minimal components, making them a popular choice for DIY hand crank generators.

- Brushless DC Motors: Although more complex than brushed motors, brushless DC motors provide higher efficiency and longer lifespan due to the lack of brushes that wear out. They are ideal for applications where consistent performance is required, particularly in generating electricity over extended periods.

- Permanent Magnet Alternators: These alternators are designed to generate AC electricity and are highly efficient at low speeds, making them suitable for hand-cranked applications. They utilize permanent magnets to produce a magnetic field, which allows for more robust power generation without requiring an external power source.

- Stepper Motors: While typically used for precise positioning, stepper motors can be utilized in hand crank generators by converting mechanical motion into electrical energy effectively. They operate in a controlled manner, allowing for consistent output, although they might require more complex circuitry for optimal performance.

- Universal Motors: These motors can operate on both AC and DC power, making them versatile for generator applications. They are capable of generating significant power output but can be less efficient compared to other motor types, especially at low speeds.

How Does a DC Motor Benefit Hand Crank Generator Efficiency?

A DC motor can significantly enhance the efficiency of a hand crank generator in several ways:

- High Efficiency: DC motors are known for their high efficiency rates, often exceeding 80%. This means that they convert a greater portion of the mechanical energy from cranking into electrical energy, maximizing the output of the generator.

- Variable Speed Operation: A DC motor can operate efficiently at various speeds, making it adaptable to different cranking speeds. This flexibility allows users to generate electricity at their own pace without a significant drop in performance.

- Simple Control Mechanisms: DC motors can be easily controlled using simple electronic components like PWM (Pulse Width Modulation) controllers. This allows for precise regulation of the motor speed and output voltage, optimizing the efficiency of energy conversion.

- Low Starting Torque Requirements: DC motors typically require less torque to start compared to AC motors. This characteristic means that less effort is needed to initiate the generator’s operation, making it easier for users to crank.

- Compact Size: Many DC motors are compact and lightweight, making them easier to integrate into portable hand crank generators. This portability is beneficial for users who need a generator that is easy to carry and set up in various locations.

- Reversibility: Most DC motors can operate in both directions, allowing them to function as both a motor and a generator. This feature can be advantageous in applications where the user needs to convert mechanical energy back into electrical energy efficiently.

What Are the Advantages of Using a Brushless Motor in Hand Crank Generators?

The advantages of using a brushless motor in hand crank generators include improved efficiency, reduced maintenance, and longer lifespan.

- Improved Efficiency: Brushless motors are designed to have less energy loss during operation compared to brushed motors. This means that more of the mechanical energy generated from cranking is converted into electrical energy, making the generator more effective in producing power.

- Reduced Maintenance: Because brushless motors do not contain brushes that wear out over time, they require significantly less maintenance. This eliminates the need for regular brush replacement and minimizes the risk of performance degradation due to wear, leading to a more reliable generator setup.

- Longer Lifespan: The absence of friction from brushes in a brushless motor contributes to its durability and longevity. With fewer moving parts prone to wear, brushless motors can operate for extended periods without failure, making them ideal for hand crank generators that may be used intermittently.

- Quieter Operation: Brushless motors typically generate less noise during operation since they lack the mechanical contact found in brushed motors. This results in a more pleasant user experience when using a hand crank generator, particularly in quiet environments.

- Better Speed Control: Brushless motors offer superior speed control and torque management, which allows for more effective power generation at varying crank speeds. Users can generate a consistent output regardless of how quickly or slowly they turn the crank, increasing overall efficiency.

What Factors Affect the Performance of a Motor in Hand Crank Generators?

Several factors influence the performance of a motor in hand crank generators:

- Motor Type: The type of motor, such as brushed or brushless, significantly affects efficiency and maintenance. Brushless motors tend to have better longevity and efficiency due to the absence of friction from brushes, making them more suitable for hand crank applications.

- Power Rating: The power rating of the motor determines how much electrical energy can be generated per unit of time. A higher power rating means the motor can produce more output when cranked, but it may also require more effort to turn, affecting user experience.

- Torque Requirements: The amount of torque needed to turn the motor is crucial for efficient operation. Motors with low torque requirements are easier to crank, allowing users to generate electricity without excessive effort, while high-torque motors may generate more power but require more physical strength.

- Gear Ratio: The gear ratio between the crank and the motor influences the rotational speed and torque. A higher gear ratio can allow for easier cranking at lower speeds, making it more user-friendly, while a lower gear ratio might provide more power at the expense of requiring higher cranking speeds.

- Magnet Strength: The strength of the magnets used in the motor contributes to its efficiency and output. Stronger magnets can enhance the magnetic field, improving the motor’s ability to convert mechanical energy into electrical energy, thus increasing overall performance.

- Efficiency: The efficiency of the motor indicates how much of the mechanical energy input is converted into electrical energy. Higher efficiency motors waste less energy as heat, providing more usable power for the generator and enhancing the overall effectiveness of the hand crank generator.

- Cooling Mechanism: Effective cooling can prevent overheating of the motor during prolonged use. Motors that have built-in cooling features or are designed to dissipate heat efficiently can maintain performance levels without damage, especially during extended cranking sessions.

How Important is Motor RPM for Hand Crank Generator Output?

Motor RPM (revolutions per minute) is crucial for the output of a hand crank generator. This is because the electrical output generated by a motor is directly proportional to its speed. Higher RPM typically leads to greater voltage and, subsequently, increased electrical power.

Key factors to consider include:

-

Voltage Output: The faster the motor turns, the more voltage it generates. Motors with a lower RPM may not produce sufficient voltage to power certain devices.

-

Efficiency: Motors that work efficiently at higher RPMs can convert mechanical energy from cranking into electrical energy more effectively. This can reduce the amount of effort needed for cranking while maintaining stable output.

-

Load Compatibility: Different loads require varying voltage levels. A motor with a suitable RPM can adjust output to meet the needs of different devices, ensuring compatibility and preventing damage.

Selecting a motor with an optimal RPM range for your hand crank generator will greatly influence the overall performance, enabling you to power lights, charge batteries, or run small appliances more effectively. Make sure to assess the application when choosing the right motor, as various devices may demand different energy outputs.

What Role Does Motor Efficiency Play in Generator Performance?

Motor efficiency is crucial for maximizing the performance of hand crank generators, as it directly affects the amount of energy converted from mechanical to electrical form.

- Energy Conversion Rate: The efficiency of a motor determines how much of the input mechanical energy is converted into electrical energy. A more efficient motor will waste less energy as heat, thereby providing more usable power output for the same amount of cranking effort.

- Load Handling Capability: An efficient motor can handle varying loads better, maintaining high performance under different electrical demands. This adaptability ensures that the generator can supply consistent power even as the load changes, making it more versatile in usage.

- Durability and Longevity: Motors that operate at higher efficiencies generally experience less wear and tear over time. This longevity means that users can rely on their hand crank generators for longer periods without needing frequent repairs or replacements, which is especially important in emergency or off-grid situations.

- Cost-Effectiveness: While efficient motors may initially cost more, their ability to produce more power with less effort can lead to savings in the long run. Users will find that a more efficient motor reduces the physical strain and time required to generate electricity, making it a worthwhile investment.

- Compatibility with Various Cranking Speeds: Efficient motors often perform well across a range of cranking speeds, allowing users to generate power at their own pace without sacrificing performance. This feature makes hand crank generators more user-friendly and accessible to people with different levels of physical ability.

What Are the Top Recommended Motors for Hand Crank Generators?

The top recommended motors for hand crank generators are:

- Permanent Magnet DC Motor: This type of motor is widely favored due to its efficiency and ability to generate good voltage output with minimal effort. It uses permanent magnets to create a magnetic field, which allows for a simpler and more compact design ideal for hand-cranking applications.

- Stepper Motor: Stepper motors are known for their precision and can be used effectively to generate power through a hand crank. They can be finely controlled to optimize the energy conversion, making them suitable for applications that require specific voltage and current outputs.

- Brushed DC Motor: These motors are straightforward and inexpensive, making them a popular choice for DIY hand crank generators. They offer a good balance between performance and cost, though they may require more maintenance due to brush wear over time.

- Brushless DC Motor: Brushless motors are highly efficient and have a longer lifespan than their brushed counterparts since they do not have brushes that wear out. They are ideal for continuous use in hand crank generators, providing steady power output with reduced maintenance needs.

- Universal Motor: A universal motor can operate on both AC and DC power, which adds versatility to a hand crank generator setup. They are capable of generating high torque at low speeds, making them effective for hand-cranking, but they may be noisier and less efficient than other motor types.

Which DC Motors Provide the Best Performance for Hand Crank Applications?

The best motors for hand crank applications typically include the following options:

- Permanent Magnet DC Motors: These motors are known for their efficiency and reliability, making them ideal for hand crank generators.

- Brushed DC Motors: These motors offer a simple design and are easy to control, which can be advantageous in hand crank setups.

- Stepper Motors: While not commonly used for traditional hand crank applications, they can provide precise control over rotation, which may be beneficial in specific designs.

- Gear Motors: These motors provide high torque at low speeds, which is particularly useful for converting manual cranking into electrical energy.

Permanent Magnet DC Motors: These motors utilize permanent magnets to create a magnetic field, resulting in high efficiency and a compact design. They are particularly effective in low-speed applications like hand cranking, where consistent torque is required to generate electricity without excessive effort.

Brushed DC Motors: Featuring a straightforward design, brushed DC motors use brushes to conduct electricity to the rotating coil. This simplicity allows for easy integration into hand crank generators, and they tend to have good torque characteristics at low speeds, making them suitable for generating power during manual operation.

Stepper Motors: Stepper motors are designed to move in precise increments, which gives users control over the output voltage and current. Although they are not typically the first choice for hand crank applications, their ability to manage precise rotations can be advantageous in experimental setups or applications requiring detailed control over energy generation.

Gear Motors: Gear motors combine a standard DC motor with a gear reduction system, significantly increasing the torque output while reducing the speed. This is particularly beneficial in hand crank generators, where the user may not be able to exert high speeds but can apply significant torque, thereby enhancing the efficiency of energy conversion.

How Do Permanent Magnet Motors Compare in Performance for Hand Crank Generators?

| Aspect | Motor A | Motor B |

|---|---|---|

| Efficiency | High efficiency, up to 90% under optimal conditions. | Moderate efficiency, around 75% which may vary with load. |

| Torque | Delivers high torque at low speeds, suitable for cranking. | Generates lower torque, may require higher cranking speeds. |

| Size | Compact design, easy to integrate into smaller generators. | Bigger size, may need more space in the generator setup. |

| Weight | Lightweight, facilitating easier handling and portability. | Heavier, could impact the overall weight of the generator. |

| Cost | Higher cost due to advanced technology. | More affordable, budget-friendly option. |

| Durability | High durability with a long lifespan, suitable for regular use. | Moderate durability, may require more maintenance. |

| Noise Level | Operates quietly, minimal noise during cranking. | Produces more noise, can be disruptive during operation. |

| Performance Rating | Highly rated by users for efficiency and ease of use. | Average ratings, users note the need for higher speeds. |

How Can You Optimize Motor Performance in Hand Crank Generators?

To optimize motor performance in hand crank generators, consider the following strategies:

-

Motor Selection: Choose a high-efficiency motor designed for low RPM (revolutions per minute) applications. Brushless DC motors are often preferred due to their efficiency and reduced maintenance needs compared to brushed alternatives.

-

Gear Ratio: Adjust the gear ratio to balance speed and torque. A higher gear ratio increases rpm but may decrease torque, while a lower ratio enhances torque at the cost of speed. Match the gear ratio to the motor’s specifications for optimal operation.

-

Load Calculation: Analyze and match the motor’s output to the expected electrical load. Oversizing or undersizing the motor can result in inefficiencies. Ensure that the motor can handle peak load demands without overheating.

-

Maintenance: Regularly lubricate moving parts and check connections for wear. A well-maintained system operates smoother, improving overall performance.

-

Torque and RPM Matching: Ensure the crank handle is ergonomically designed to facilitate the required torque without causing operator fatigue. An easy-to-grip handle can enable more consistent energy input.

Implementing these strategies will lead to improved efficiency and reliability in your hand crank generator system.

Related Post: