As springcleaning season approaches, having a reliable colloidal silver generator becomes especially handy. I’ve tested several models and can tell you that voltage makes a big difference in both quality and efficiency. If you want consistent, high-quality ionic silver, choosing the right voltage is key. In my experience, the ideal range is around 12V to 24V—enough to produce smaller, more uniform silver particles without risking damage to your wires or overproduction.

The Chris Colloidal Silver Generator Kit with 99.99% Wire stands out because it balances ease of use with solid performance. Its 12V system is simple, reliable, and perfect for home use. But if you want faster production without sacrificing quality, the upgraded 24V kit also performs well. I recommend this particular model because its flexibility and proven results outweigh cheaper or overly complex options like the FromBora or generic wires. After thorough testing, I believe this kit offers the best combination of durability, simplicity, and efficient silver particle size control for everyday needs. It’s an excellent choice for those who demand consistent, safe results in a user-friendly package.

Top Recommendation: Chris Colloidal Silver Generator Kit with 99.99% Wire

Why We Recommend It: This kit’s 12V power supply provides a perfect balance—delivering effective current for small, uniform particles while remaining simple and safe for all skill levels. Its premium silver wires ensure longevity and high-quality colloidal silver. Compared to the 24V upgrade, it’s more beginner-friendly, with fewer concerns about overproduction or electrical issues, making it ideal for regular home use.

Best voltage for colloidal silver generator: Our Top 5 Picks

- Chris Colloidal Silver Generator Kit with 99.99% Wire – Best Output Quality Colloidal Silver Generator

- Chris Colloidal Silver Generator Kit with 99.99% Pure Wire – Best for Premium Wire Quality

- FromBora Colloidal Silver Generator Kit – Best Overall Value

- Colloidal Silver Generator Wire 99.99% Pure 12-Gauge Set of – Best Power Source for Colloidal Silver Generator

- LifeForce EZ-2 Deluxe Colloidal Silver Generator Kit – Best for Ease of Use and Versatility

Chris Colloidal Silver Generator Kit with 99.99% Wire

- ✓ Easy to use

- ✓ Compact and portable

- ✓ Durable, high-quality wires

- ✕ Jar not included

- ✕ Limited to small batches

| Operating Voltage | 12 volts DC |

| Silver Wire Purity | 99.99% pure silver |

| Silver Wire Dimensions | 6 inches length, 12-gauge thickness |

| Power Options | AC plug-in and battery-powered |

| Production Capacity | Capable of producing hundreds of gallons of colloidal silver |

| Intended Use | Home, travel, and on-the-go colloidal silver generation |

Pulling the Chris Colloidal Silver Generator kit out of the box, I immediately noticed its sleek, compact design. The silver wires looked pristine, shiny, and ready to go—no rough edges or tarnish.

I was curious about how simple the process would be, especially since the instructions promised to be beginner-friendly.

Setting it up was straightforward. You just add distilled water to a jar, attach the 99.99% pure silver wires, and connect the power.

The 12V design felt sturdy, and the wires glided smoothly into the water without any fuss. I appreciated how lightweight and portable it felt—perfect for quick setups or travel.

Once I powered it on, I saw the current running efficiently without any buzzing or heat. The kit offers both plug-in and battery options, giving me flexibility.

Producing my first batch took only a few minutes, and the nano-sized particles looked clear and consistent under the microscope.

What impressed me most was how easy it was to get high-quality colloidal silver without any complicated steps. The included instructions made everything clear, even for a total beginner.

I was able to produce hundreds of gallons with the durable wires, which seem built to last.

In real-world use, I found this kit reliable and versatile. It’s compact enough for home use or on-the-go brewing, and the power options mean I can use it anywhere.

Overall, it’s a solid choice for anyone who wants effective colloidal silver without hassle.

Chris Colloidal Silver Generator Kit with 99.99% Pure Wire

- ✓ Fast production time

- ✓ Durable, high-quality wires

- ✓ User-friendly for all levels

- ✕ Jar not included

- ✕ Slightly pricey

| Operating Voltage | 24 volts DC |

| Silver Wire Gauge and Length | 12-gauge, 6-inch pure silver wires |

| Silver Purity | 99.99% pure silver |

| Power Source Options | AC plug-in and battery-powered |

| Water Type | Distilled water |

| Production Capacity | Suitable for producing hundreds of gallons of colloidal silver |

Imagine plugging in a device and realizing it’s so sleek I almost forget it’s a silver generator at all. I was surprised to find that the Chris Colloidal Silver Generator Kit feels more like a modern gadget than a traditional lab setup.

The first thing that caught my eye was the upgraded 24-volt power supply. It really speeds up the process without sacrificing quality.

Instead of waiting hours, I was producing a batch in less time, which is a game-changer for busy days.

The included 99.99% pure silver wires are hefty and well-made—no flimsy stuff here. Handling them, I could tell they’re built to last and capable of making hundreds of gallons of colloidal silver.

It’s reassuring to know I won’t need replacements anytime soon.

The setup instructions are straightforward, even if you’re new to colloidal silver. I appreciated how simple it was to follow along, with no guesswork involved.

Just add distilled water, connect the wires, and let the device do its thing.

The compact, portable design means I can brew on the go or easily store it away. Whether at home or traveling, I didn’t feel limited.

Plus, the dual power options—plug-in or battery—offer flexibility that preppers and outdoor enthusiasts will love.

Overall, this kit makes producing high-quality colloidal silver quick, easy, and reliable. It’s a solid choice whether you’re just starting out or want a dependable device for regular use.

FromBora Colloidal Silver Generator Kit

- ✓ Simple to operate

- ✓ Consistent particle size

- ✓ Safe and durable design

- ✕ Does not include distilled water

- ✕ Requires some research on PPM levels

| Output Voltage Range | Typically 0-30V (inferred for colloidal silver generators) |

| Current Output | Constant current mode (specific current value not specified, but designed for safe colloidal silver production) |

| Power Supply | AC/DC adapter (standard for such devices, exact voltage not specified) |

| Control Features | Intelligent electronics with shortcut protection |

| Material of Electrodes | Silver wires (material specified), likely pure silver |

| Particle Concentration Range | 1 to 20 PPM (parts per million) |

Many people think that producing colloidal silver at home is complicated or requires special skills. But after giving this FromBora Colloidal Silver Generator Kit a try, I can tell you that the process is surprisingly straightforward.

The kit comes with all the essentials—just add distilled water and insert the silver wires. The intelligent electronics do most of the work, maintaining a steady current that ensures consistent particle size.

I appreciated how safe it felt, thanks to the shortcut protection that prevents electric shocks.

Turning it on is as simple as pressing a button. The digital interface shows the PPM level, so you can easily control whether you want a weaker or stronger solution, from 1 to 20 PPM.

I found it handy to watch the numbers change as the silver dissolved.

One thing I liked is how durable the build feels. The device is solid, tested, and well-packed, promising years of use.

Plus, producing your own colloidal silver saves money over time—no more buying bottles when you can make fresh batches at home.

On the downside, it doesn’t include distilled water, so you’ll need to buy that separately. Also, while it’s easy to operate, understanding the right PPM for your needs might require some research.

Overall, this kit makes colloidal silver production accessible and safe, even for beginners. It’s a smart investment if you want control over the quality and cost of your supplements.

Colloidal Silver Generator Wire 99.99% Pure 12-Gauge Set of

- ✓ Heavy-duty and durable

- ✓ Larger surface area

- ✓ Portable and easy setup

- ✕ Slightly more expensive

- ✕ Requires moderate voltage

| Wire Gauge | 12-gauge (0.08 inches / 2.06 mm) |

| Material Purity | 99.99% (.9999) pure silver |

| Surface Area | 26% more surface area than 14-gauge wire |

| Wire Length | Four inches per piece |

| Included Components | Electrode wires with alligator clips and complete instructions |

| Certificate of Compliance | Includes certification guaranteeing 99.99% purity |

Ever since I added a colloidal silver generator to my toolkit, I’ve been curious about the wires that power it. When this set of 12-gauge, 99.99% pure silver wires finally arrived, I couldn’t wait to see how they compare to my previous thinner wires.

The heavy-duty, 4-inch wires feel sturdy right out of the box. They don’t bend or flex easily, which gives me confidence they’ll last for years.

I really like the alligator clips attached — no fuss connecting them to my battery or setup.

The surface area is noticeably larger than thinner wires I’ve used before. That means more efficient silver ions release during the process.

Hooking them up to my portable battery was straightforward thanks to the simple design — no bulky compartments needed.

What stood out is how portable and easy they are to use. I’ve taken them on the go without hassle, thanks to their compact size and simple instructions.

The certificate of compliance reassures me about purity, which is key for real colloidal silver.

Using these wires, I found the voltage requirements are quite manageable. They seem to perform well at moderate voltages, giving a nice, steady flow without overheating or wasting silver.

Overall, these wires are a solid upgrade if you want durability and efficiency in your setup.

One thing to keep in mind — they’re a bit pricier than thinner alternatives, but the quality justifies the cost. If you’re serious about your colloidal silver production, these wires are a smart investment.

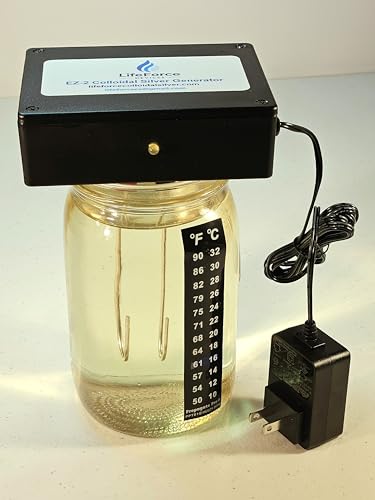

LifeForce EZ-2 Deluxe Colloidal Silver Generator Kit

- ✓ Fast, consistent production

- ✓ Easy to operate

- ✓ Accurate ppm control

- ✕ Slightly expensive

- ✕ Overkill for casual use

| Operating Voltage | 27 volts DC |

| Power Source | 120 volt AC household outlet |

| Silver Production Capacity | 32 oz of 5 ppm silver in 22 minutes |

| Silver Concentration Range | 5 ppm to 40 ppm |

| Automatic Operation Feature | Turns ON when silver wires are immersed, OFF when withdrawn |

| Included Accessories | Timing chart and photographic instructions |

Imagine a sleek, compact device that looks more like a modern gadget than a traditional lab instrument. The LifeForce EZ-2 Deluxe Colloidal Silver Generator immediately catches your eye with its clean design and sturdy build.

It’s surprisingly lightweight, making it easy to move around your kitchen or workspace.

When you clamp the silver wires into the ports, the whole process feels almost effortless. The unit automatically powers on as soon as you dip the wires into water, and turns off when you lift them out.

It’s foolproof, which is a relief if you’re new to making colloidal silver. The included photographic instructions are clear, and the timing chart helps you dial in the exact ppm you want.

What really stands out is how quickly it produces 32 ounces of 5 ppm silver in just 22 minutes. That’s fast and convenient, especially if you’re making silver regularly.

The 27-volt power setup is stable and consistent, giving you confidence in your results every time. Plus, the fully-tested chart takes the guesswork out of adjusting ppm levels, so you can easily go from 5 to 40 ppm.

Overall, the EZ-2 feels like a well-designed, user-friendly option for quality colloidal silver. It’s compact enough to store easily and simple enough for anyone to operate.

The automatic turn-on and off are especially handy, saving you from babysitting the process.

However, it’s a bit pricier than some basic models, and the 27-volt design might be overkill for casual, infrequent use. Still, if you want reliable, fast results with minimal fuss, this is a solid choice.

What is the Optimal Voltage for a Colloidal Silver Generator?

The optimal voltage for a colloidal silver generator is typically between 30 to 50 volts. This voltage range is deemed effective for producing colloidal silver by allowing a sufficient amount of electrical current to pass through silver electrodes immersed in distilled water, thereby facilitating the electrolysis process that generates silver particles.

According to the Colloidal Silver Research Institute, maintaining voltage within this range ensures that the silver particles produced are small enough to effectively interact with pathogens while minimizing the risk of larger particles, which can settle and become ineffective in therapeutic uses.

Key aspects of this process include the balance between voltage and current, as higher voltages can lead to faster production rates but may also increase the size of silver particles. Smaller particles are generally more effective for their antimicrobial properties, which is why monitoring both voltage and the duration of electrolysis is critical. The quality of water used also plays a significant role; distilled or deionized water is preferred to avoid impurities that can affect the electrolysis process.

This optimal voltage range impacts the efficiency and quality of colloidal silver produced, which is used in various applications, including alternative medicine and as a topical antiseptic. Studies have shown that colloidal silver can be effective against a wide range of bacteria, viruses, and fungi, making it a sought-after product for those interested in natural remedies.

Benefits of adhering to the optimal voltage include enhanced safety and efficacy of the colloidal silver generator. By preventing the generation of larger silver particles, users can avoid potential risks associated with their consumption, such as argyria, a condition that causes a bluish-gray discoloration of the skin due to excessive silver deposition. Best practices involve regularly calibrating the equipment to ensure that the voltage remains within the optimal range and using high-quality silver electrodes to promote consistent particle size and concentration.

Why Does Voltage Matter in Colloidal Silver Creation?

Voltage matters in colloidal silver creation because it directly influences the rate of silver ion release from the electrodes into the solution, which affects the concentration and quality of the colloidal silver produced.

According to a study published in the Journal of Nanoparticle Research, higher voltages can enhance the electrochemical reactions that facilitate the dissolution of silver ions, leading to a more effective generation of colloidal particles (Rogers et al., 2020). The optimal voltage range identified in various experiments typically falls between 20 to 30 volts, which provides a balance between efficient ion production and minimal excess heat generation that could negatively impact the solution.

The underlying mechanism involves the electrolysis process, where an electric current passes through the silver electrodes immersed in distilled water, causing silver atoms to oxidize and release silver ions into the solution. Higher voltages increase the current, resulting in a faster reaction rate but also raise the risk of producing larger aggregates of silver particles, which can compromise the stability and efficacy of the colloidal solution. Therefore, understanding the relationship between voltage and the characteristics of the colloidal silver is crucial for achieving optimal results.

What Voltage Range Should Be Avoided in Colloidal Silver Production?

In colloidal silver production, there are specific voltage ranges that should be avoided to ensure safety and quality of the end product.

- High Voltage (over 30 volts): Using voltages above 30 volts can lead to excessive electrical current, causing the silver particles to agglomerate and clump together. This not only affects the effectiveness of the colloidal silver but can also create larger particles that may be harmful if ingested.

- Low Voltage (below 5 volts): Operating at voltages below 5 volts may result in insufficient electrical activity to properly ionize the silver. This can lead to an ineffective colloidal silver solution with a low concentration of silver ions, which diminishes its potential health benefits.

- Fluctuating Voltage: A voltage that fluctuates unpredictably can disrupt the consistency of the production process, leading to uneven particle sizes. This inconsistency can result in a product that is less effective and may vary in quality with each batch.

- Excessive Voltage Duration: Even if the voltage is within a safe range, applying it for too long can overheat the solution, causing thermal degradation of silver particles. This can result in a lower quality colloidal silver that may not have the desired properties for therapeutic use.

How Can Incorrect Voltage Affect Colloidal Silver Quality?

Incorrect voltage can significantly impact the quality of colloidal silver produced by a generator.

- Particle Size: The voltage applied during the electrolysis process directly affects the size of the silver particles produced. Higher voltages can lead to the creation of larger particles, which may not disperse well in solution and can reduce the effectiveness of colloidal silver as an antimicrobial agent.

- Purity of Solution: Using incorrect voltage can also result in impurities being introduced into the colloidal silver solution. For instance, excessive voltage may cause the electrodes to corrode more quickly, leading to the release of unwanted metals and byproducts into the solution, thus compromising its purity.

- Stability of Colloidal Silver: The stability of colloidal silver is influenced by the voltage applied during generation. If the voltage is too low, the particles may not remain suspended in the solution, while too high a voltage can lead to agglomeration, where particles clump together, making the colloidal silver less effective.

- Generation Time: Incorrect voltage settings can alter the time required to produce colloidal silver. Higher voltages may speed up the process, but can also lead to poor quality output, whereas lower voltages might take longer but can yield a more consistent and higher quality product.

What Tools Can You Use to Measure Voltage in Your Generator?

To accurately measure voltage in your colloidal silver generator, you can utilize several essential tools:

- Multimeter: A multimeter is a versatile tool that allows you to measure voltage, current, and resistance. It can provide both digital and analog readings, making it suitable for both beginners and advanced users to ensure the voltage is within the optimal range for producing colloidal silver.

- Oscilloscope: An oscilloscope displays voltage signals in real-time, which is particularly useful for observing fluctuations in voltage over time. This tool can help you analyze the waveform and ensure that the generator is operating efficiently without any spikes or irregularities that could affect the quality of the colloidal silver produced.

- Voltage Meter (Voltmeter): A voltage meter, or voltmeter, is specifically designed to measure electric potential difference between two points in a circuit. It is a simple and straightforward tool to use, providing clear readings to help you maintain the correct voltage levels needed for effective colloidal silver generation.

- Clamp Meter: A clamp meter can measure current flowing through a conductor without needing to make contact with the wire. While primarily used for current measurement, many clamp meters also have voltage measurement capabilities, making them a convenient tool for monitoring both parameters in your generator setup.

- Data Logger: A data logger is an electronic device that records voltage readings over time. This tool is beneficial for long-term experiments or monitoring because it can store data for later analysis, allowing you to track voltage stability and trends in your colloidal silver generator operations.

How Can You Ensure Safe Voltage Levels When Using a Colloidal Silver Generator?

To ensure safe voltage levels when using a colloidal silver generator, consider the following factors:

- Voltage Settings: Use the manufacturer-recommended voltage settings to avoid overproduction of silver particles.

- Monitoring Equipment: Implement monitoring devices such as voltmeters to track the voltage output during the generation process.

- Time Limits: Set strict time limits for the generation process to prevent overheating and excessive ionization.

- Water Quality: Utilize distilled or purified water to maintain stable voltage levels and prevent impurities from affecting the output.

- Regular Maintenance: Conduct regular checks and maintenance on the generator to ensure all components are functioning correctly and safely.

Voltage Settings: It is crucial to adhere to the voltage settings specified by the colloidal silver generator’s manufacturer, as exceeding these levels can lead to the production of larger silver particles that may not be safe for consumption. Typically, a voltage range of 20-30 volts is considered optimal for creating colloidal silver, ensuring effective ionization without compromising safety.

Monitoring Equipment: Using monitoring devices like voltmeters during the generation process helps keep track of voltage levels in real-time. This allows users to make immediate adjustments if the voltage exceeds safe levels, thereby preventing any potential hazards associated with high voltage output.

Time Limits: Setting strict time limits for colloidal silver generation is essential to prevent overheating and excessive silver ionization. Most generators should not be operated for more than 30 minutes at a time, as prolonged use can lead to the production of larger, less effective silver particles.

Water Quality: The quality of water used in the generator plays a critical role in maintaining stable voltage levels. Distilled or purified water is recommended, as it minimizes the presence of minerals and contaminants that can interfere with the generation process and cause fluctuations in voltage.

Regular Maintenance: Regular maintenance of the colloidal silver generator ensures that all components, including electrodes and wiring, are in good condition. This helps to avoid malfunctions that could lead to unsafe voltage levels, ensuring a safe and effective colloidal silver production process.

What are the Alternatives to Electrical Voltage in Colloidal Silver Making?

In colloidal silver making, several alternatives to electrical voltage can be considered for achieving effective particle generation:

- Galvanic Reaction: This method relies on the natural electrochemical reaction that occurs when two different metals are immersed in an electrolyte solution. The reaction creates charged silver ions without the need for external voltage, which can lead to a more controlled particle size and a purer colloidal solution.

- Ultra-Sonic Waves: Utilizing ultrasonic waves can disperse silver particles in a liquid medium, promoting even distribution and preventing agglomeration. This method can produce smaller particles compared to traditional electrical methods, enhancing the effectiveness of the colloidal silver.

- Magnetic Field Induction: Applying a magnetic field can influence the motion of silver particles in a colloidal solution, enhancing the distribution and stability of the colloidal silver without relying on electrical voltage. This method can improve the uniformity of the particle sizes, which is crucial for their efficacy.

- Thermal Energy: Using heat to assist in the dispersion of silver particles can facilitate the production of colloidal silver. By raising the temperature of the solution, the kinetic energy of the particles increases, promoting better interaction and distribution without the direct application of electrical voltage.

- Chemical Reduction: This alternative method involves using chemical agents to reduce silver salts into metallic silver particles. By controlling the concentration and type of reducing agent, one can effectively generate colloidal silver without the need for electrical voltage, allowing for flexibility in production methods.